We are passionate, skilled professionals who provide a bespoke and highly versatile surface repair and maintenance service to help protect and strengthen roads and pavements. Being the leading specialist hand-applied micro asphalt contractor, we leave no stone unturned to deliver work of exceptional quality, carried out by our expert team who are passionate about a job-well-done.

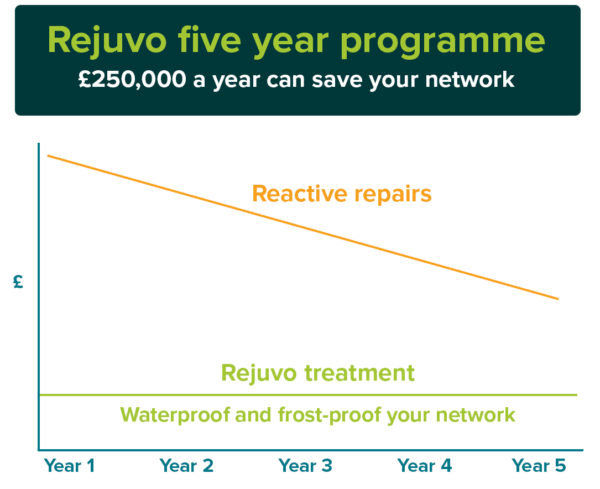

At Rejuvo JPCS we are on a mission to help budget controllers make their money go further. Alongside reactive repairs, we use our specialist product range for preventative protection to maintain carriageways and footways, significantly prolonging their lifespan to help budgets go further.